Current location:Home > double lip oil seal >

double lip oil seal

2025-08-14 13:50

2025-08-14 13:48

2025-08-14 13:47

The oil seal's primary function is to prevent oil leakage, which is critical in maintaining lubrication and preventing contamination within the system. A well-functioning oil seal ensures that oil remains where it is needed, reducing friction and wear on machine parts A well-functioning oil seal ensures that oil remains where it is needed, reducing friction and wear on machine parts A well-functioning oil seal ensures that oil remains where it is needed, reducing friction and wear on machine parts A well-functioning oil seal ensures that oil remains where it is needed, reducing friction and wear on machine parts

A well-functioning oil seal ensures that oil remains where it is needed, reducing friction and wear on machine parts A well-functioning oil seal ensures that oil remains where it is needed, reducing friction and wear on machine parts 70x90x10 oil seal. The 20% oil content in the seal's composition may imply that it is made of a blend of materials that includes 20% oil, which could enhance its flexibility and resistance to temperature fluctuations and physical stress.

70x90x10 oil seal. The 20% oil content in the seal's composition may imply that it is made of a blend of materials that includes 20% oil, which could enhance its flexibility and resistance to temperature fluctuations and physical stress.

A well-functioning oil seal ensures that oil remains where it is needed, reducing friction and wear on machine parts A well-functioning oil seal ensures that oil remains where it is needed, reducing friction and wear on machine parts

A well-functioning oil seal ensures that oil remains where it is needed, reducing friction and wear on machine parts A well-functioning oil seal ensures that oil remains where it is needed, reducing friction and wear on machine parts 70x90x10 oil seal. The 20% oil content in the seal's composition may imply that it is made of a blend of materials that includes 20% oil, which could enhance its flexibility and resistance to temperature fluctuations and physical stress.

70x90x10 oil seal. The 20% oil content in the seal's composition may imply that it is made of a blend of materials that includes 20% oil, which could enhance its flexibility and resistance to temperature fluctuations and physical stress.

...

2025-08-14 13:43

2025-08-14 13:36

2025-08-14 13:18

2025-08-14 13:16

2025-08-14 12:47

2025-08-14 12:24

2025-08-14 12:11

Latest articles

The design must be such that it balances the need for a tight seal with the amount of friction generated during operation. Excessive friction can lead to wear and heat buildup, while insufficient sealing can allow fluid leakage. Therefore, engineers carefully select materials and dimensions to ensure optimal performance.

rotary lip seal

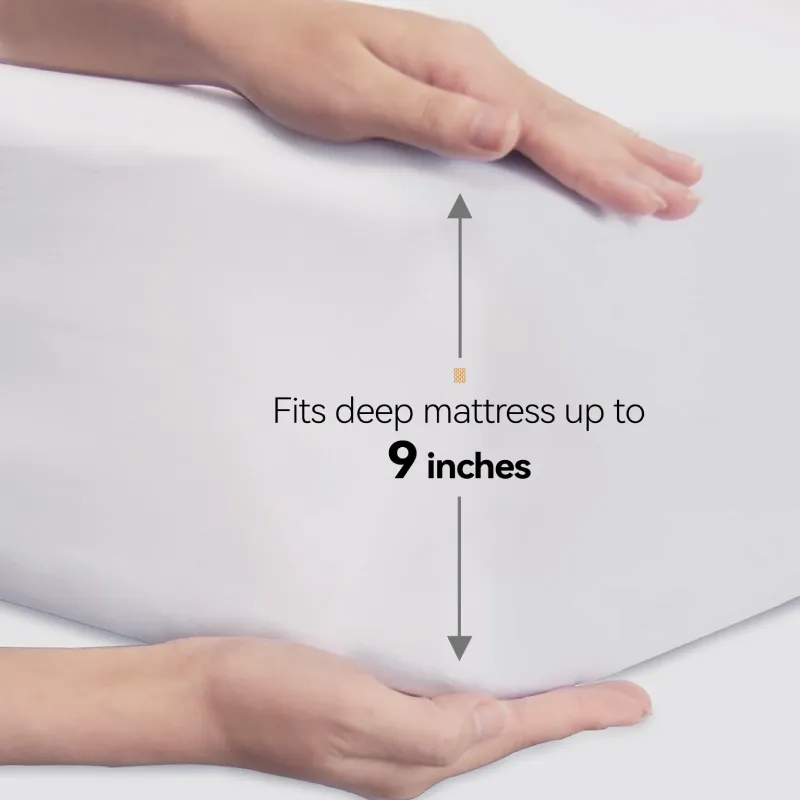

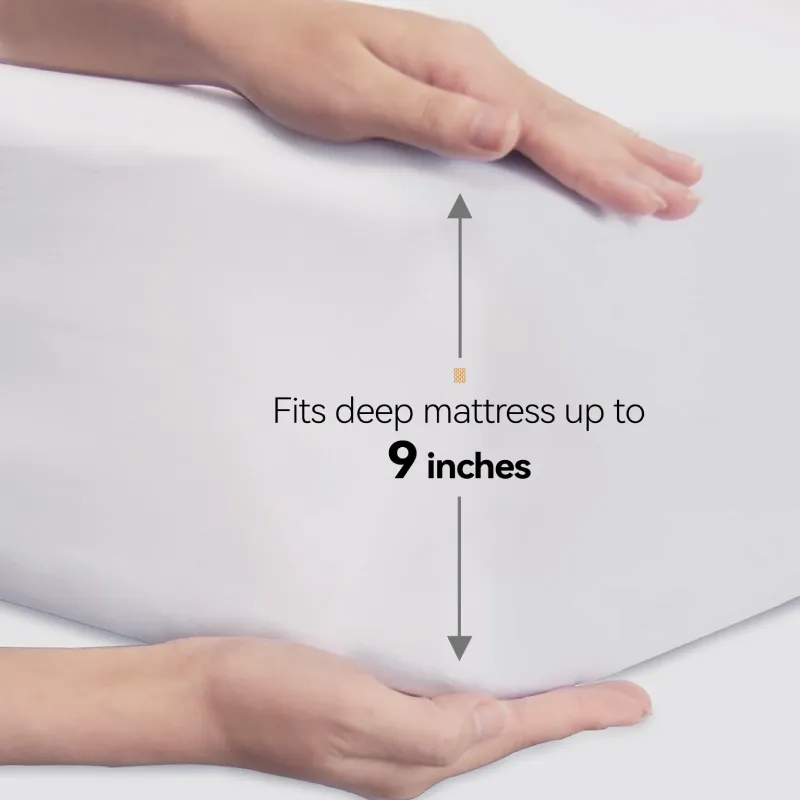

When combined, these two fibers create a fabric that combines the best of both worlds springs sheets 50 cotton 50 polyester. The 50/50 cotton-polyester blend offers a balance between the natural softness and breathability of cotton and the durability and low-maintenance properties of polyester. The result is a sheet that feels smooth and comfortable against the skin while being resilient enough to withstand regular use and washing.

springs sheets 50 cotton 50 polyester. The 50/50 cotton-polyester blend offers a balance between the natural softness and breathability of cotton and the durability and low-maintenance properties of polyester. The result is a sheet that feels smooth and comfortable against the skin while being resilient enough to withstand regular use and washing.

springs sheets 50 cotton 50 polyester. The 50/50 cotton-polyester blend offers a balance between the natural softness and breathability of cotton and the durability and low-maintenance properties of polyester. The result is a sheet that feels smooth and comfortable against the skin while being resilient enough to withstand regular use and washing.

springs sheets 50 cotton 50 polyester. The 50/50 cotton-polyester blend offers a balance between the natural softness and breathability of cotton and the durability and low-maintenance properties of polyester. The result is a sheet that feels smooth and comfortable against the skin while being resilient enough to withstand regular use and washing.